No Ice, Please!

If there’s one thing on an airplane that pilots really want to work when they need it to work, it’s their deice system!While there are several deice systems used on General Aviation aircraft today, the pneumatic boot system is easily the most prevalent. The concept of inflating rubber boots to break off accumulating ice on the leading edge of the wings, propeller, and tail of an airplane came of age in the 1930’s. By World War II, it was the standard. For example, the G-21 Grumman Goose was offered with a deice system in 1937, as were Douglass and Lockheed offerings. It’s still the go-to technology for modern day aircraft.

Here’s how the system works:

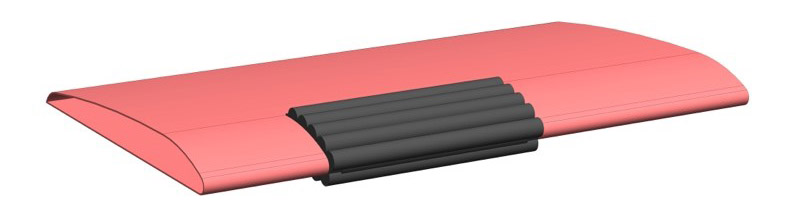

Thin, two-layered rubber strips, more commonly referred to as “boots”, are glued to the surfaces of the wings and tail’s leading edge where ice commonly accumulates. Flat tubes run the length of the boots, from the fuselage out towards the tip of the wings and tail surfaces. The whole boot lies flat against the surface when it isn’t inflated to avoid obstructing the aerodynamic design of the wings and tail (Figure 1).

Seems pretty simple, right? Well, it’s actually quite complex and a lot has to happen between the pilot flipping that switch and the boots inflating!

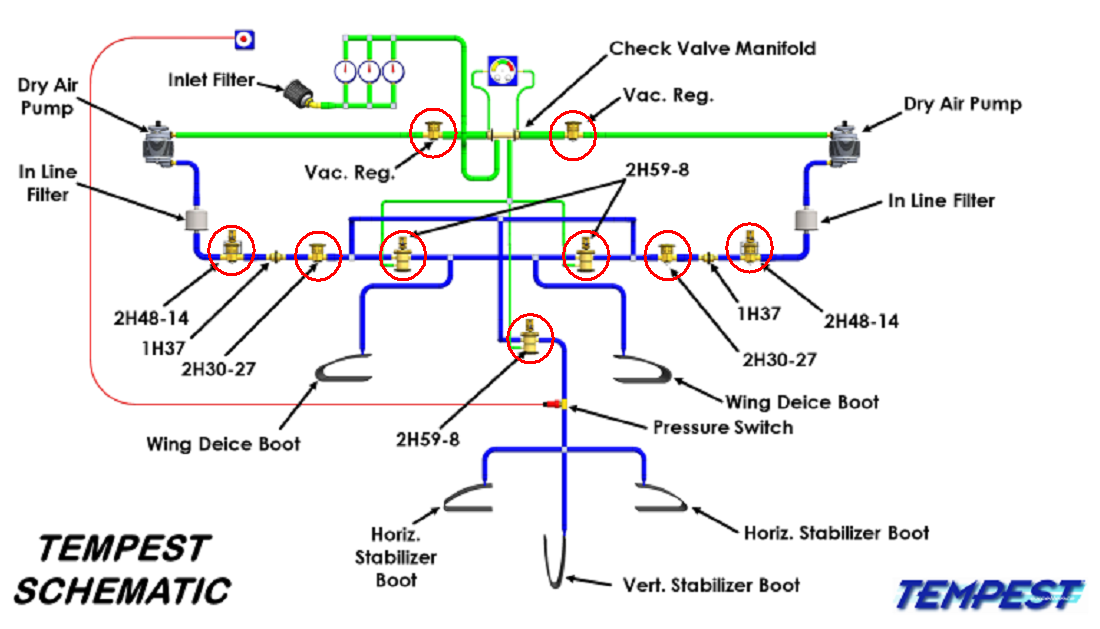

The deice system is comprised of a complex series of pumps, switches, timers, regulators, valves, and of course, the boots!

The airplane outfitted with a deice system is typically equipped with at least one, but probably two, engine-driven air pumps that provide pressure or vacuum to help inflate the deice boots (Figure 3).

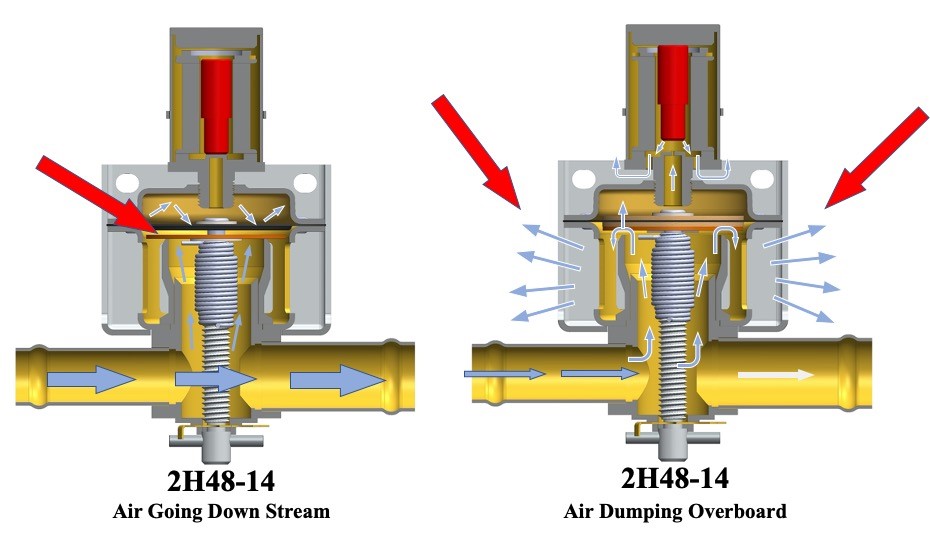

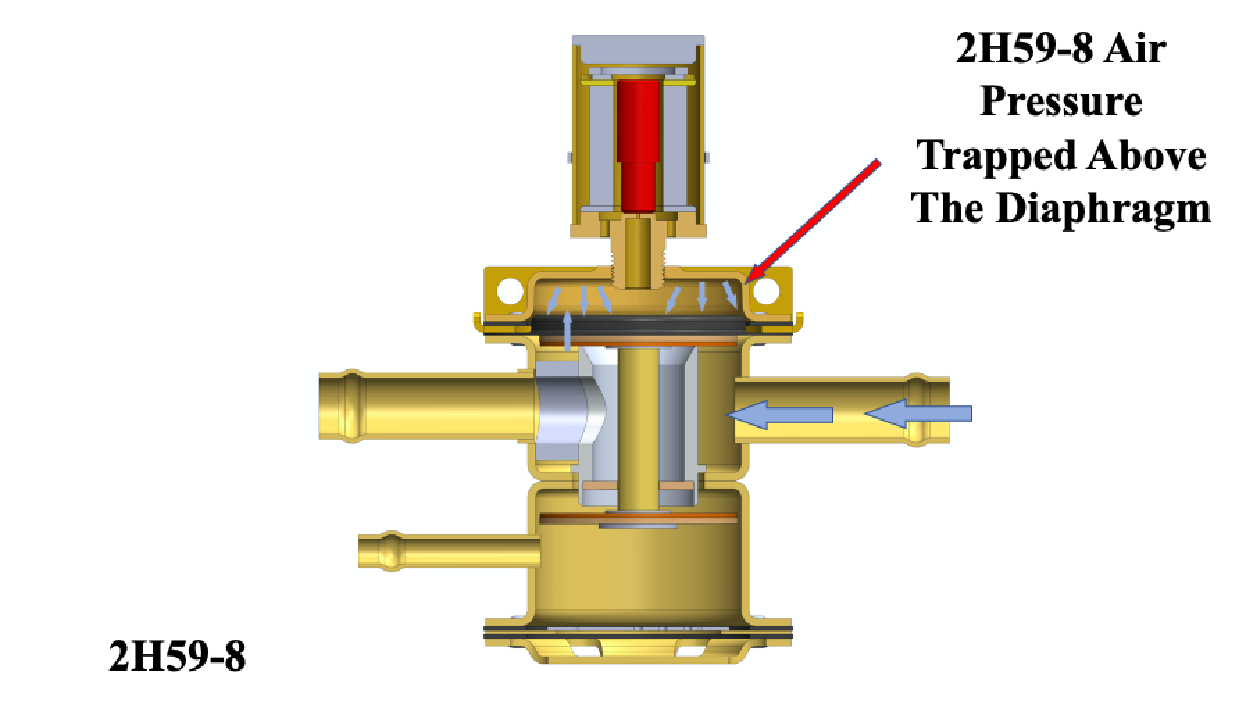

However, when the system is activated it creates high pressure that’s required for boot operation. This is all controlled by an electro-pneumatic control valve, basically the “deice on or off switch”. When the pilot flips the deice switch on, the control valve boosts the pressure in the system high enough to efficiently inflate the boots – about 15-18 psi normally.

When the boots are off, this same valve simply dumps all or most of the air pump’s pressure output overboard (Figures 4 and 5).

A timer turns the boot on (inflates them) for about six seconds, then deflates them for about a minute. This time cycle prevents overheating the pumps and gives ice time to accumulate to a thickness that is brittle and will break and be blown away the next time the boots inflate.

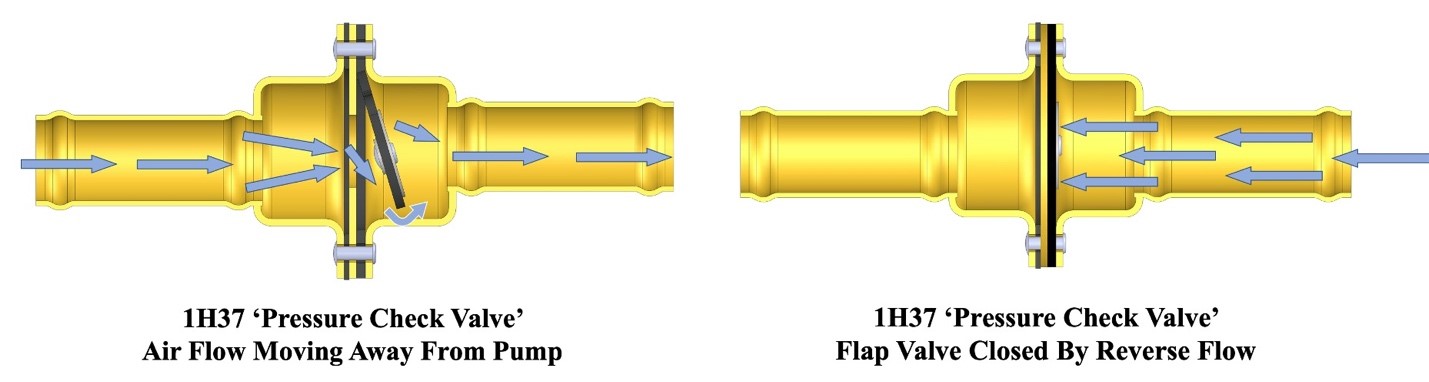

In most twin-engine airplanes, and some singles, two air pumps are used and isolated from one another so that if one pump becomes inoperative – or an engine is feathered on a twin, rendering that pump inoperable – the remaining pump can still operate the deice system. Special isolator valves (Figure 6) in the system provide this critical function and, more often than not, aren’t serviced or replaced as frequently as they should be to ensure proper performance.

In these cases, another electro-pneumatic valve redirects some suction from the air pump’s inlet to the boots to suck them flat, or suction from a vacuum inducer (a small venturi device integral to the valve) is connected to the boots to suck them flat (Figure 7).

Either way, it’s more complexity added to the already highly choreographed dance involved in making the de-icing system work.

Sometimes these switches illuminate an annunciator light on the instrument panel that informs the pilot that the boots on the tail of the airplane have attained working pressure and are staying inflated for the correct period of time. Switches are another layer of detail and complexity, but that’s an entirely different subject for another time!

That’s the basic system in a nutshell. It’s actually even more complex than described here, but that’s the gist.

Unfortunately, many pilots and aircraft owners generally ignore these lesser known, yet equally critical, components of the deice system. Most of these components are just there and, generally, work as they should when they’re asked. However, many of the planes equipped with these valves, for instance, are 30, 40, or more years old and are often still using the original components that were installed at the factory. The valves, solenoids, rubber diaphragms, gaskets, and seals in the valves and regulators age like many other aircraft components and can become stiff or brittle and sometimes crack. This can lead to becoming functionally defective, largely ineffective, or inoperable. When you need them, they may try to work, but simply can’t get the job done as intended.

There are many airplanes for which the deice system is part of a minimum equipment list but have been through many annuals without the component parts of the deice system being inspected, overhauled, or replaced with new components.

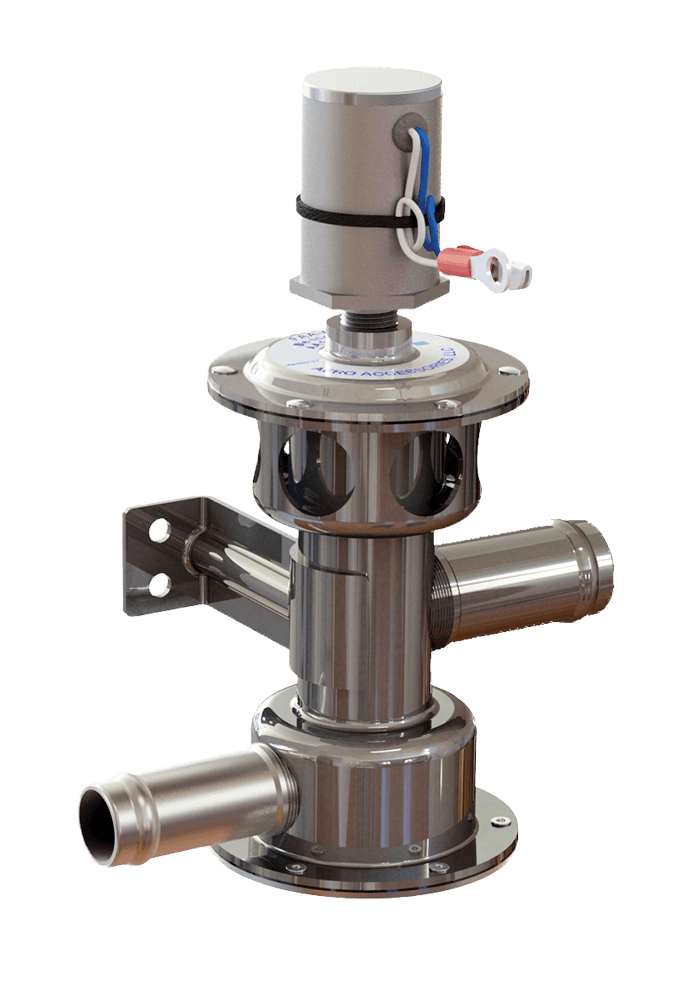

Manufacturers of these critical components, such as Aero Accessories, the manufacturer of Tempest brand products, advises that these valves, regulators, and other deice control components be repaired whenever necessary and replaced or overhauled at least every 10 years. Many operators and pilots are not aware of the necessity of periodic valve replacement or overhaul to maintain the aircraft in airworthy condition.

Aero Accessories has been building new and overhauled Tempest valves, regulators, and manifolds for decades. Like most Tempest products engineered, built, and manufactured by Aero Accessories, they include improvements in materials and design that legacy and competitive brands simply don’t offer. With the most expansive portfolio of readily available components, some of the fastest overhaul lead- times in the industry and an ever expanding line of new valves, many of which exceed their predecessors’ technologically and rival their overhauled counterparts in pricing, Tempest valves, regulators, and manifolds are as reliable as they are affordable. For full applicability or to purchase a new or overhauled deice valve, please visit the link below.

And remember, diligent inspection, maintenance, and overhaul/replacement of these critical components will help ensure that your deice system performs as needed, when needed.